Sign up for The Wanderful newletter

Join our growing community of people looking to live the simple life!

Let’s build your van now

Join our growing community of people looking to live the Simple Life

)

One of the things I love most about the Extruded Aluminum (8020) material is how strong it is. A huge factor to its strength is in the way that it’s fastened to the van.

To learn how to fasten extruded aluminum cabinets to your van, be sure to check out this video or keep reading!

When it comes to fastening 8020 Extruded Aluminum to the framing of your van, something you’re going to want to get very familiar with is Rivnuts. You’re going to be using a lot of them!

If you know how rivnuts work, then you know how to attach 8020 to your vehicle.

A rivnut (also known as a rivet nut) is a special type of nut that provides a threaded insert for bolts to be threaded into. It’s installed into a prepared hole in a piece of metal and secured prior to threading in the bolt.

A special installation tool is required to secure the nuts into the hole.

Now you have a nice threaded insert where you can thread machine screws or bolts directly into the frame of the vehicle.

One tip, when using rivnuts, is that you’ll probably find different terms being used:

I found rivnut and rivet nuts to be the same thing. Plus Nuts, on the other hand, are a bit different. I’ve heard that plus nuts are actually a bit better but with the rivnut tool I purchased, it didn’t work very well as I wasn’t able to get the proper compression.

I’m doing a metric build. If you’re using wood, this doesn’t really mean anything. But when working with 8020 it does matter because I’m buying metric size extrusion profiles. I’m buying 30 mm and 40 mm. In the U.S. it would be one inch and an inch and a half. So I’m using the 30 series and 40 series, and my rivnuts match my bolts. My bolts are also standard or metric sizes.

I’m using:

So now that you know the answer to fastening 8020 to the vehicle is rivnuts, let’s talk about the hardest part of using them…

The hardest part about using rivnuts is the upfront planning that’s required.

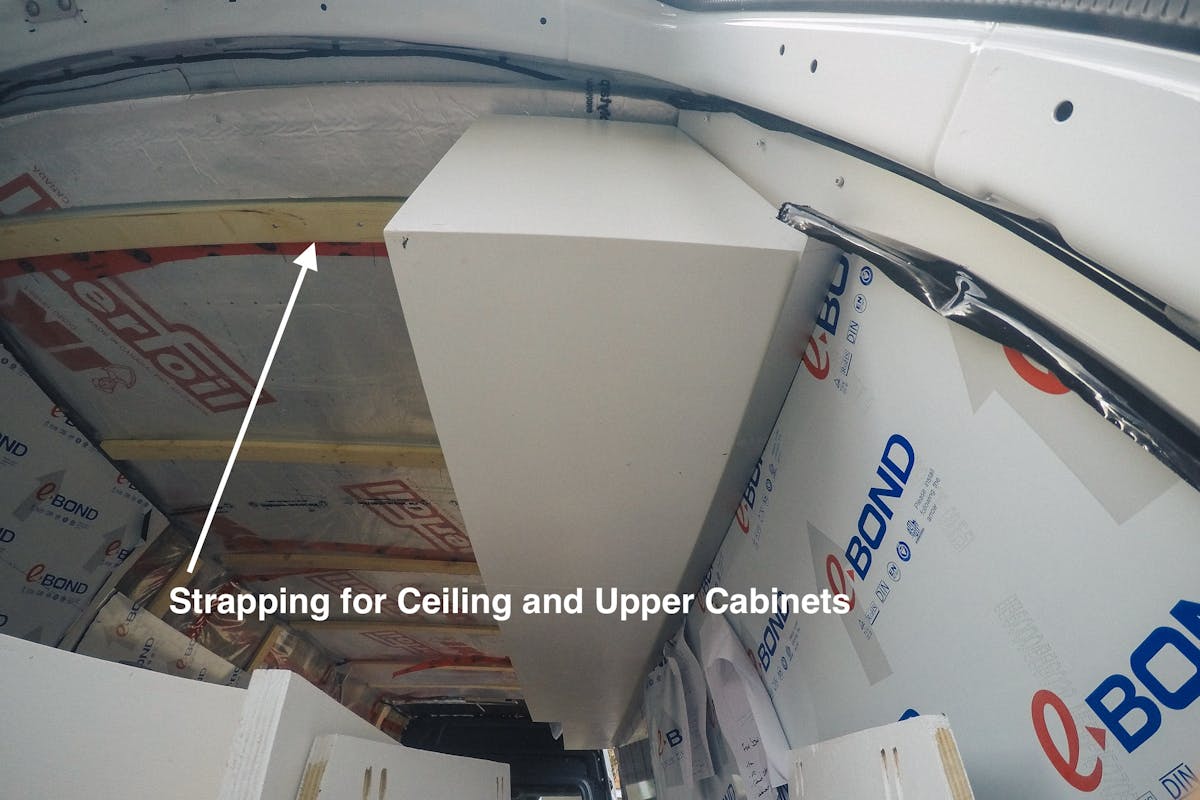

When you use wood, you use wood strapping and you just know roughly where that strapping is. As long as you know where your strapping is, you can just fire in a screw there.

These rivnuts are precise threaded inserts into the vehicle so you have to know precisely where that threaded insert is so you can thread it through other materials, such as your ceiling panels.

I hope you’ve enjoyed learning how I use rivnuts to attached 8020 to the framing of the vehicle.

For more DIY Van Build Tips, stories, and guides, be sure to subscribe to my YouTube Channel so you don’t miss any videos.

)

Are you trying to decide between Wood or 8020 Aluminum cabinets for your van conversion?

)

Are you about to kick off a journey of learning how to convert a van into a camper? Read this before wandering down the aisles of your local hardware store!

)

The topic of plumbing in a DIY Van Build is one of the most complex topics, and an area I get a lot of questions about.