Summary

The solar and electrical system on the van was one of the most daunting tasks during the entire build process.

If I’m being honest

This was the project that I had the least amount of knowledge on, so it required the most amount of research. So hopefully this break down of my electrical and solar system will help you plan out yours.

One of the hardest parts of sizing your solar system is to determine just how big of a system you need to meet your daily usage. The reason it takes so much time and effort is because most people have never really had to think about their daily power consumption.

So if you want to be lazy and avoid the need for all calculations you can just copy my exact system and never have to worry about it. I run;

- Electric induction cooktop,

- Fridge / freezer combo,

- Kettle, blender,

- Lights, water pump,

- Charge a computer,

- Charger cameras,

and many other things and have never had any issues.

Tools used

Install Process

Installing all of the electrical components certainly isn’t as straightforward as some of the other aspects of the van build. When it comes to the electrical component of the van you need to have a basic understanding of AC home wiring, DC Low voltage wiring and the solar system components.

For the purpose of this article I am not going to go into that much detail on the actual wiring of the AC and DC circuits and will focus more on the components that make up the solar system and how I have them connected together.

One thing that is very important to understand is that I am not a licensed electrician nor do I have any formal training with installing solar systems. So use all this information at your own risk.

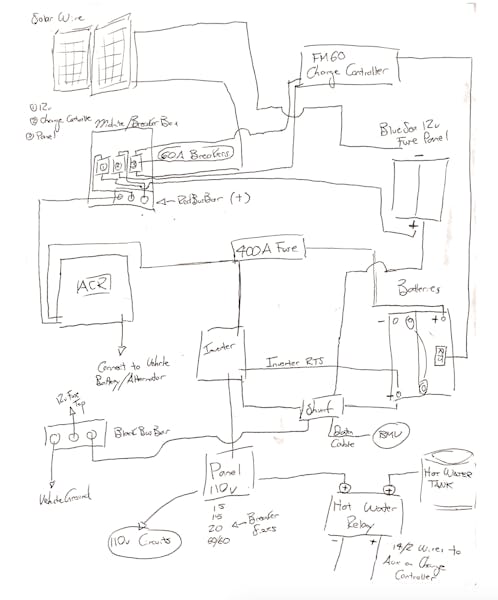

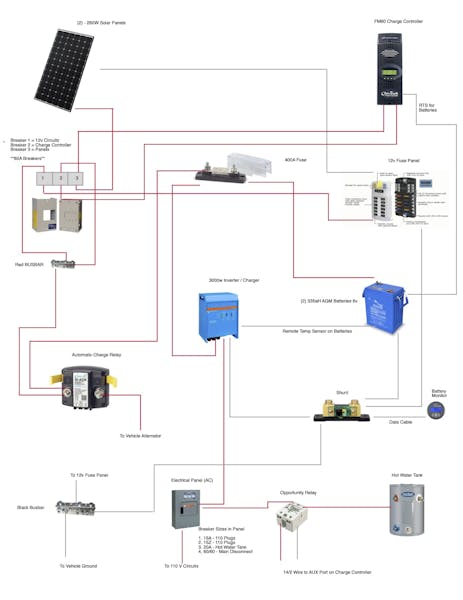

The Solar System Setup

What wire where?

For most of the connections in my system, I used a variety of welding cable and wire sizes. It takes a bit of time to map out where you’re going to place everything but once you have everything roughly in position it’s easy to see how much wire you are going to need. I know you can order all the cables pre made but I recommend buying the cable and cutting it to length yourself, then fastening all lugs on site. When using a variety of solar components you won’t always have matching cable ends as one end might be a 5/16 lug and the other a ⅜ lug. Making your own cables on site isn’t a lot of extra work, and it will make the job a lot cleaner in the end.

What wire sizes did I use?

-

4/0 Welding Cable Red and Black

Enough to get from the battery boxes to the batteries I wasn’t able to get red 4/0 so just had to use black. The 4/0 welding cable was used to connect the batteries together and the inverter to the fuse and shunt.

-

0 or 1/0 Welding Cable

For Battery 400A Fuse to ACR to DC Box Red

Connecting ACR to engine battery = Red

For General Ground to the Busbar then to the Shunt and the Busbar to vehicle ground. (Black Wire)

-

6/3 Wire AC (White Jacket)

5ft of it to connect the inverter to the breaker panel for the 110

-

6 Gauge Welding Cable Red/Black

Since I was only able to get black, I used a combination of black and some red wire from the 6/3 cable above. This was used to connect the charge controller, 12v Fuse Panel (main) and panels into the breaker box.

I used welding cable because it’s very flexible and easy to work with. If welding cable is hard to locate try phoning some welding supply shops or you can substitute for machine tooling wire.

Let’s start at the solar panels… because I need to pick somewhere to start.

Let’s Begin

For my panels I used (2) 260W Solar Panels from HESPV giving me a total of 560W. My panels are mounted on the custom roof rack and due to the size of these selected panels I do have the ability if needed to upgrade to (2) 330W panels increasing the total solar power from 520 – 660W = 140W. So far the current panel size has been adequate and getting a larger panel has not been necessary.

Once the panels are mounted, take one end of each panel and connect them together and then take the remaining 2 ends and connect them to the additional solar wire you purchased and run that inside the vehicle.

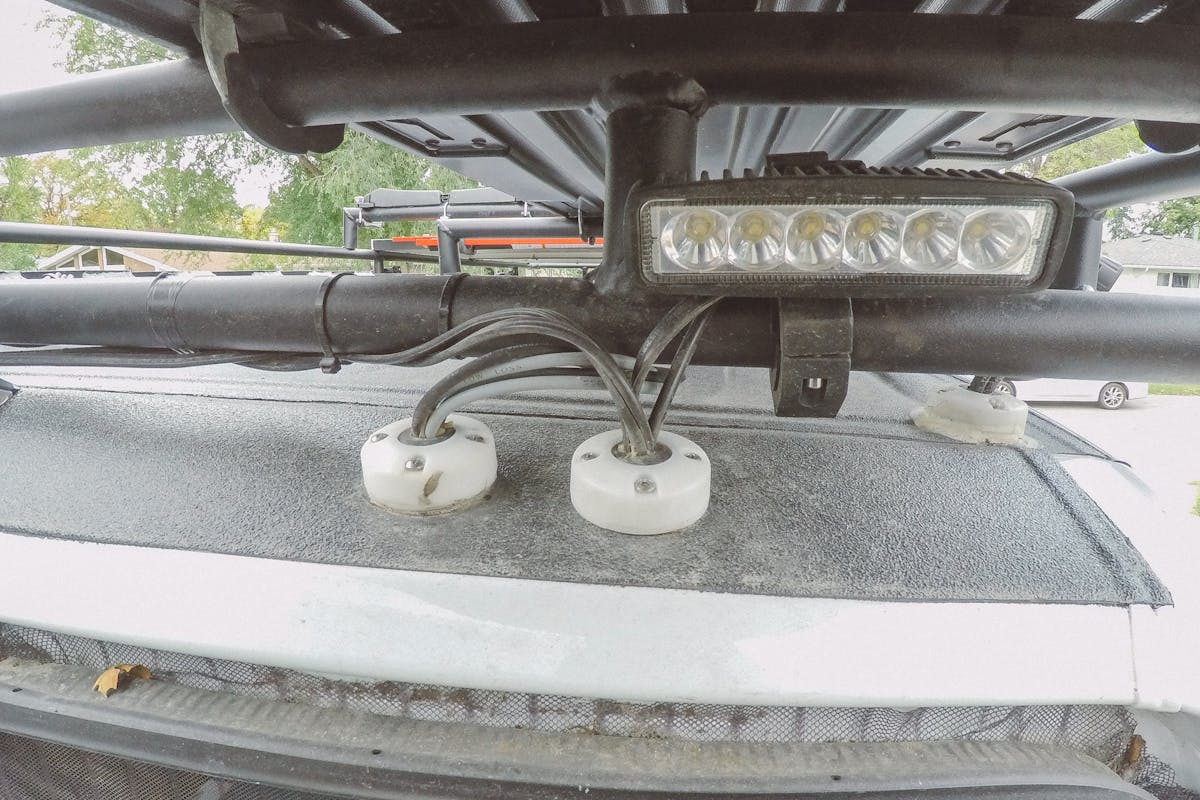

The area around this Cable Clam started to rust and it was driving me crazy…. So I had the roof sprayed to solve that problem.

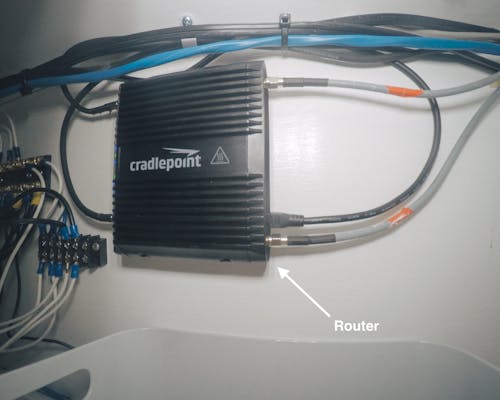

To pass the wires into the vehicle I used the Blue Sea Cable Clam, these are typically used in marine applications but they seem to work great for waterproofing the area where you need to bring wires inside the van. For my van I used three of them, the first for the solar wires, the second for the router antenna wiring and the third for the rack lighting.

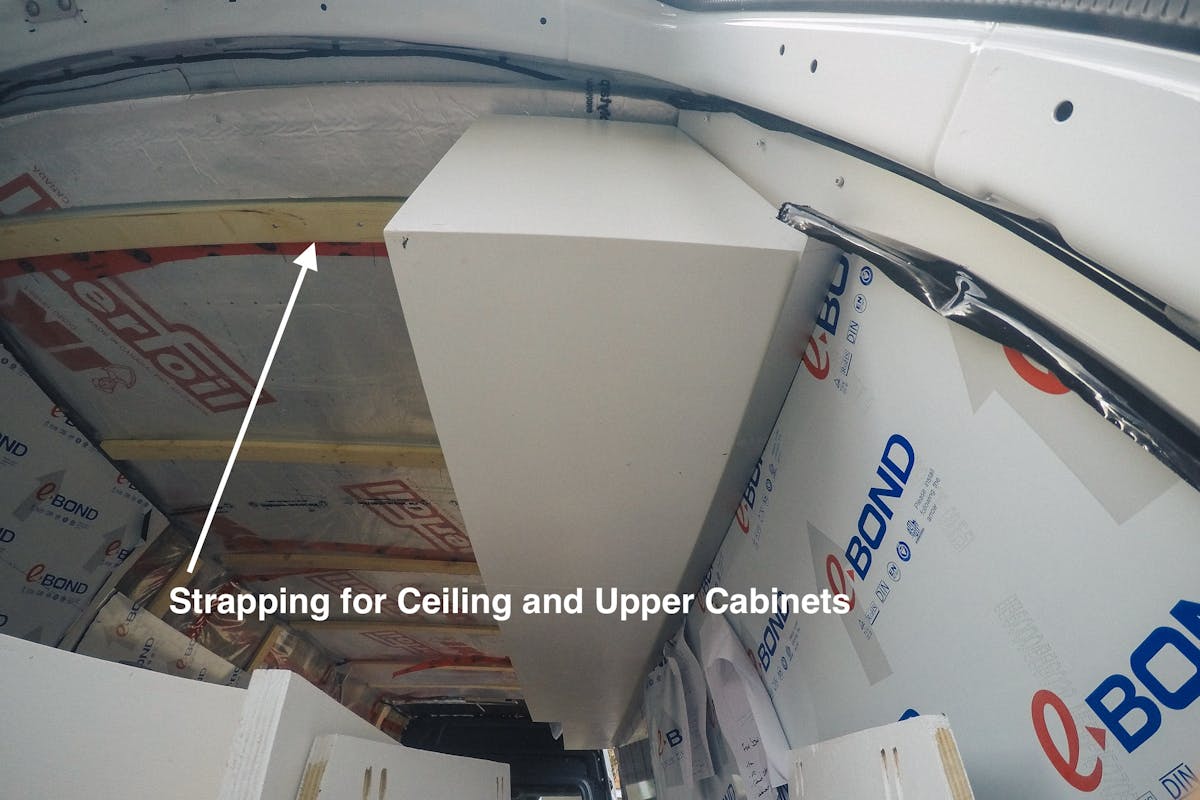

When installing these on the roof I suggest putting them as far back as you can on the sprinter van in the cavity above the rear doors. By putting the cable clam here you end up with a nice area inside the van to hide and fish the wires into whatever cabinet you are hoping to run them.

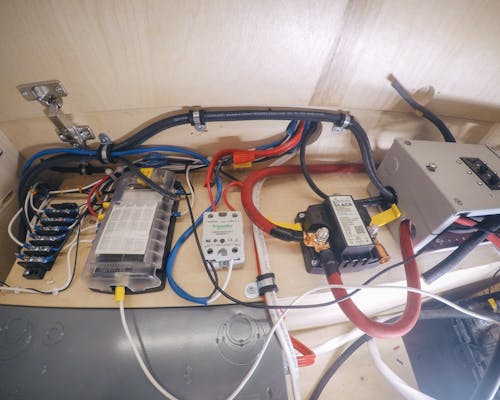

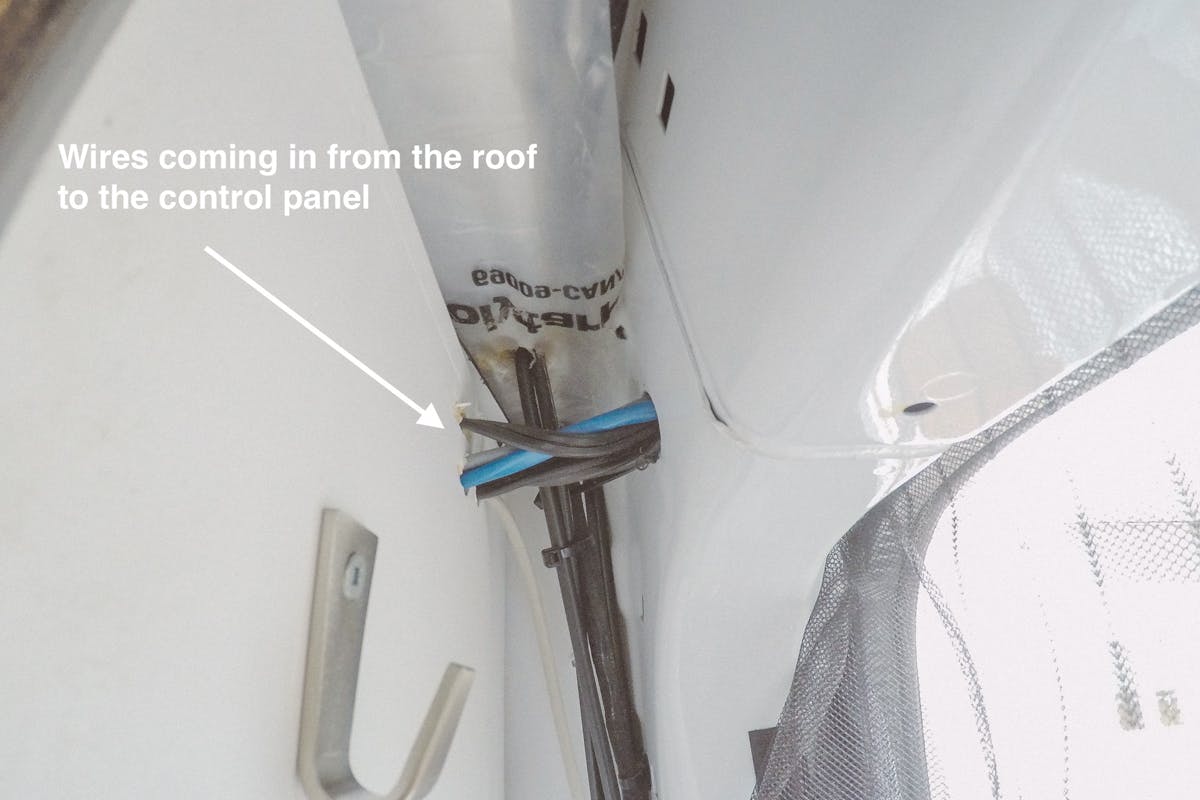

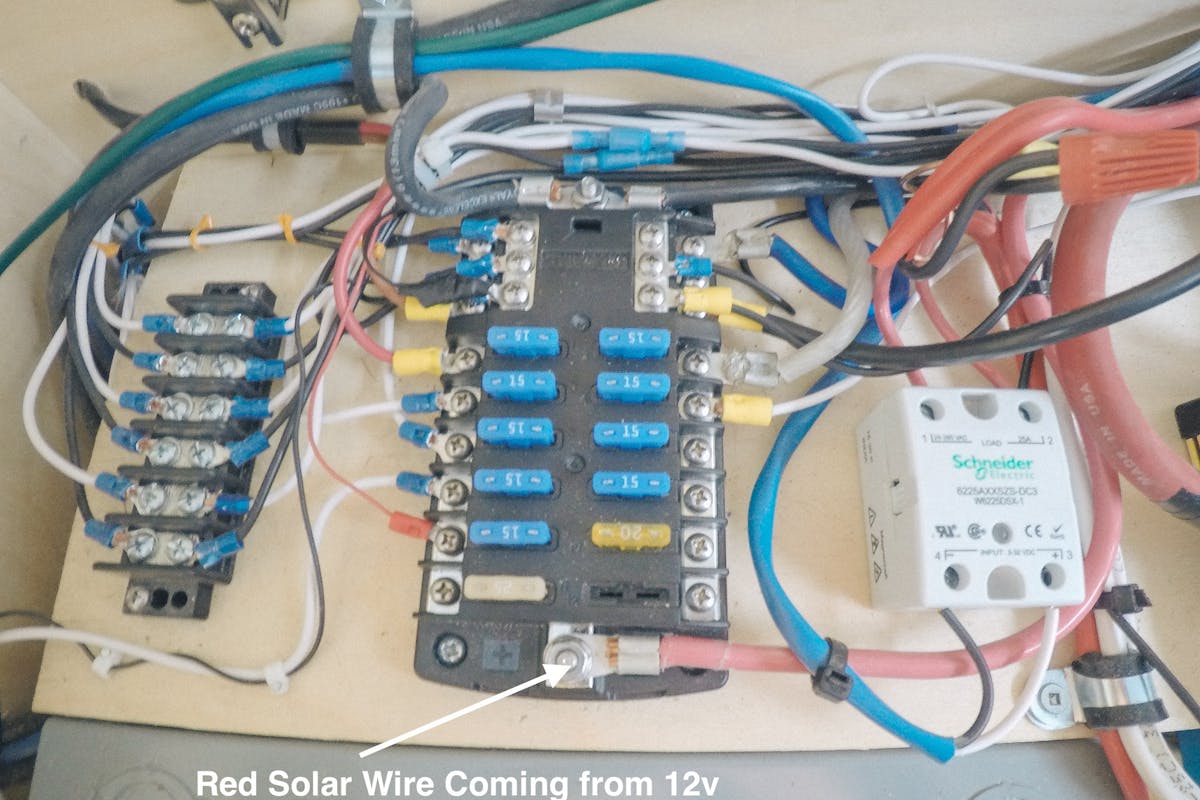

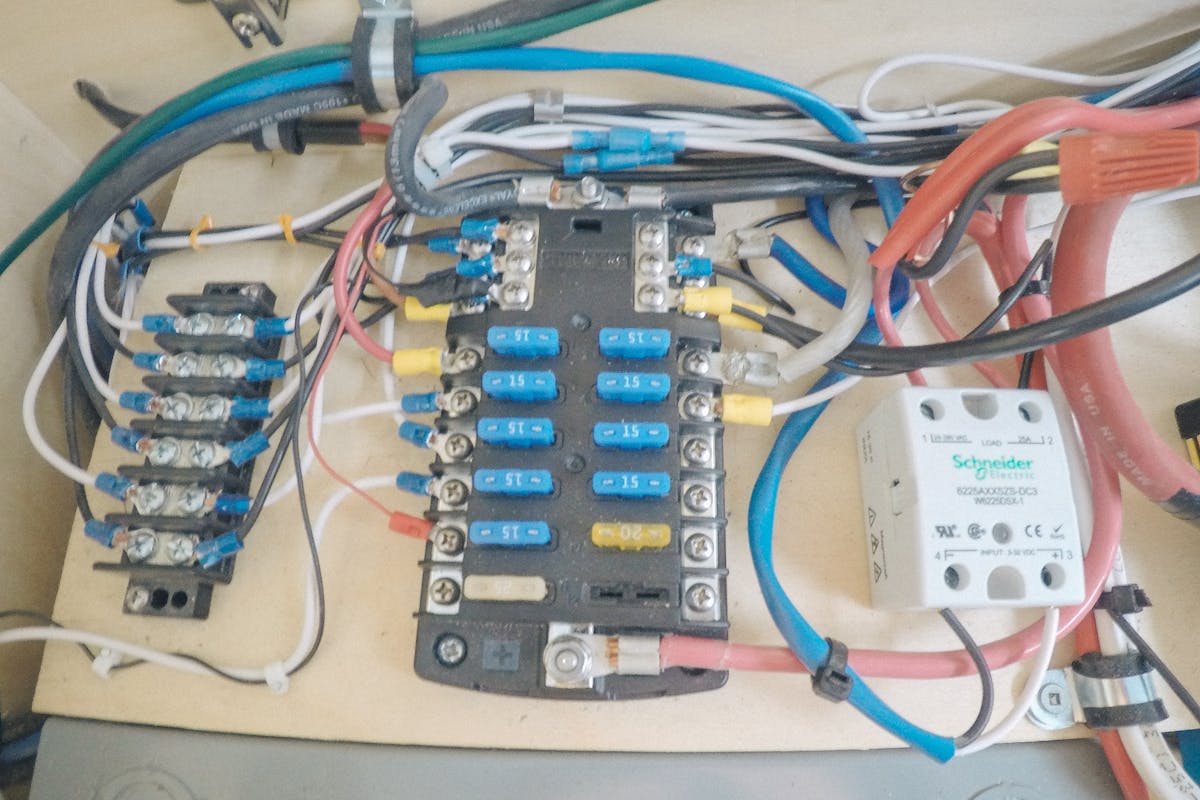

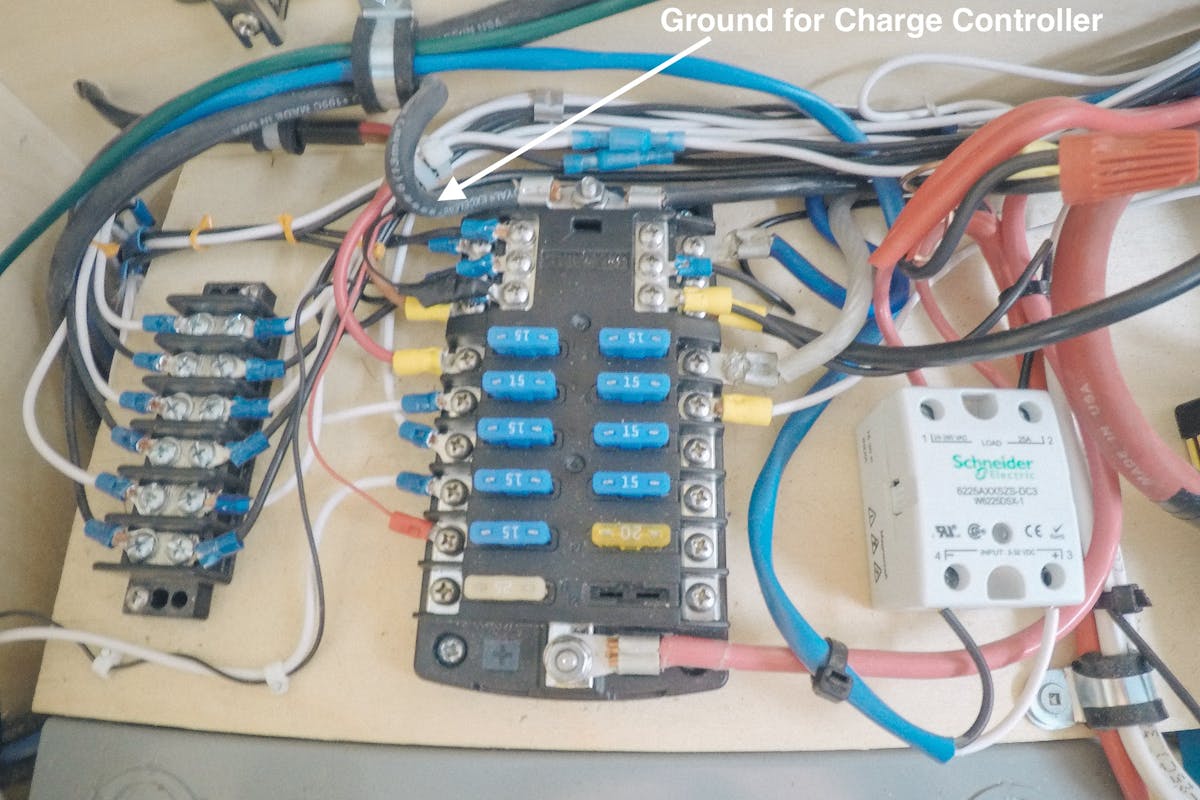

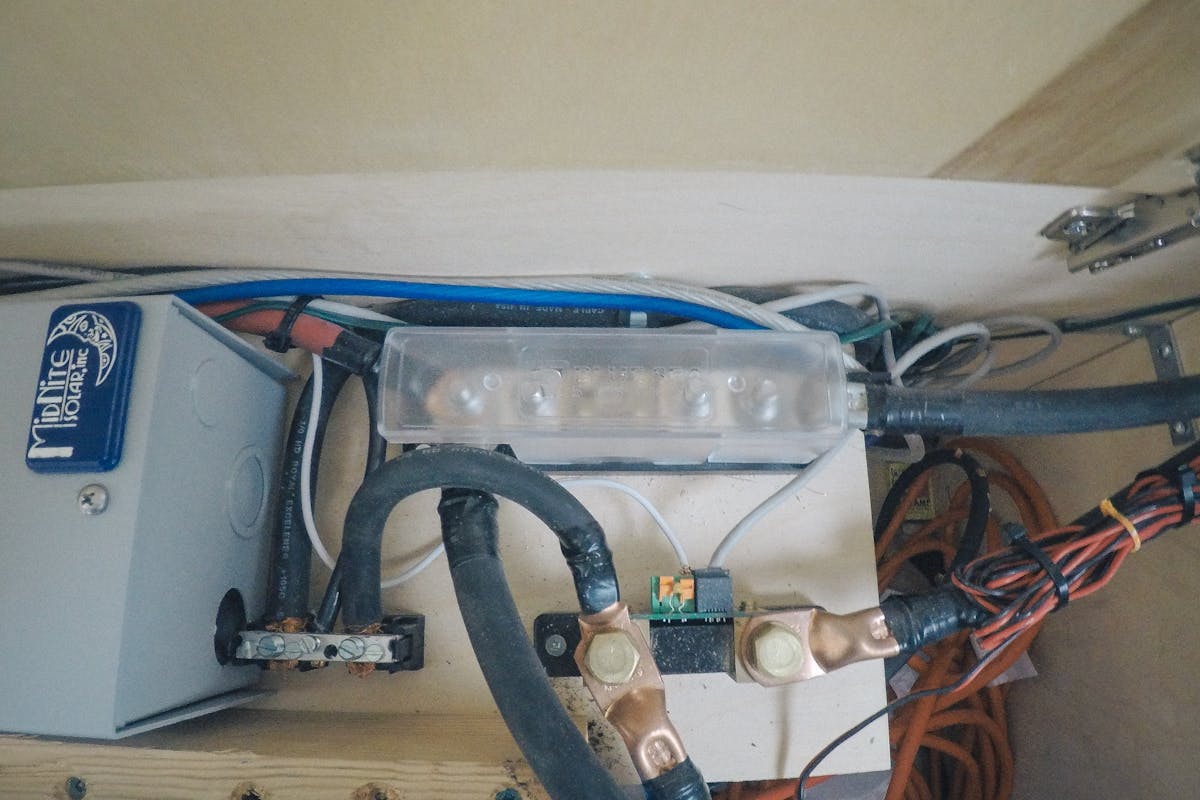

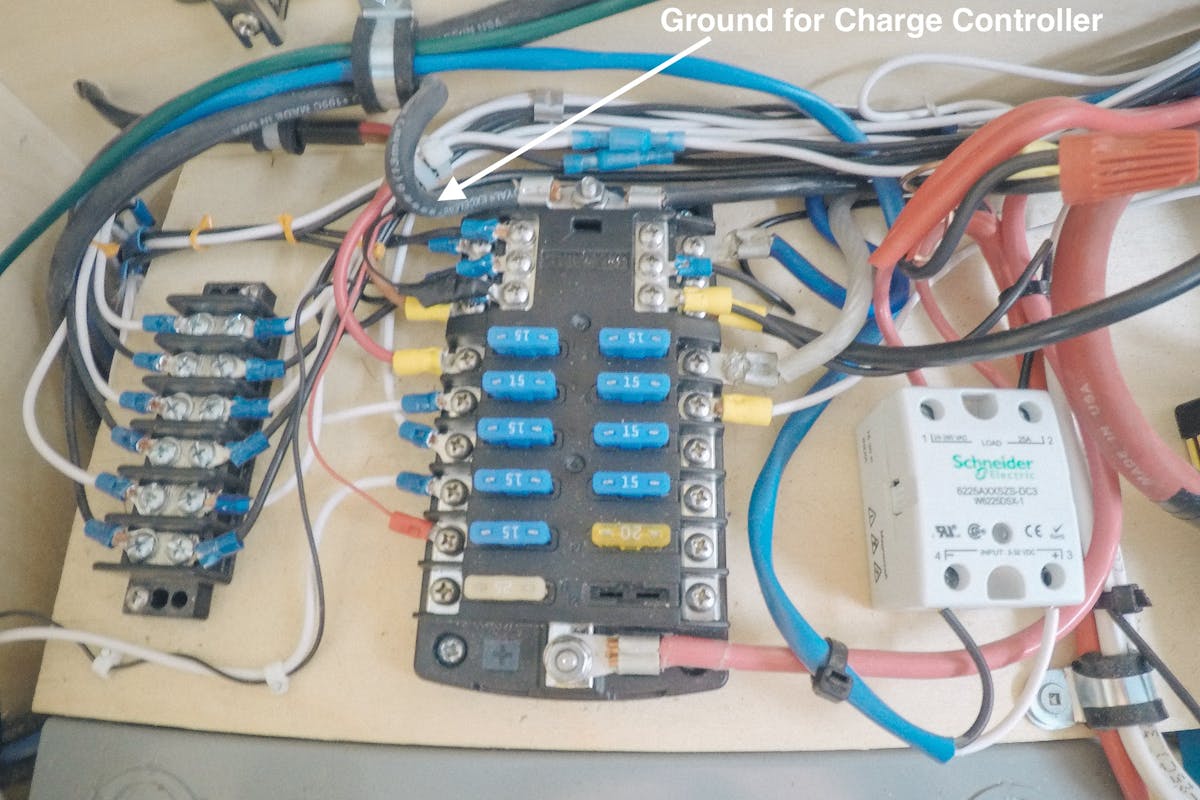

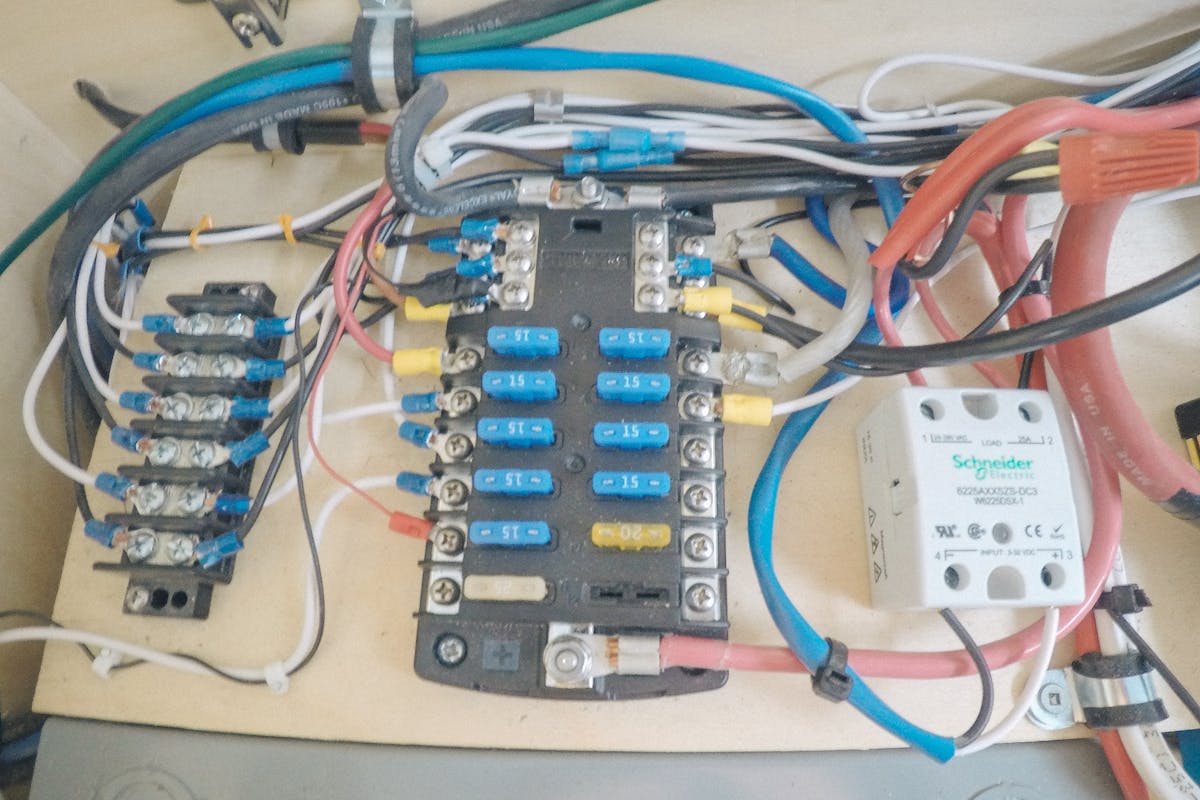

Once the solar wires are inside the vehicle the real fun begins… The negative wire on the solar panels I terminated it on the 12v Blue Sea Fuse Panel.

The second positive wire from the panels I brought into the Midnite solar breaker panel. Inside the breaker panel I have a single positive bus bar mounted inside as seen here

with 3 60A breakers the 3 breakers control

- All 12v circuits

- Charge Controller

- Solar Panels

In position 1 of the breaker panel the top wire goes to the red busbar inside the box and same with the top side of the position 2 breaker.

On the bottom side of position 1 I ran that wire to the positive of the 12v BlueSea fuse Panel

In position 2 the bottom wire was ran to the charge controller to act as a main shut off for that solar charge controller.

In position 3 the top of the breaker is running to the charge controller and the bottom is the positive side of the solar wire and this allows me to shut off the panels completely if I need to perform any work on the panels, as you never want to disconnect the panels on the roof while they are under load.

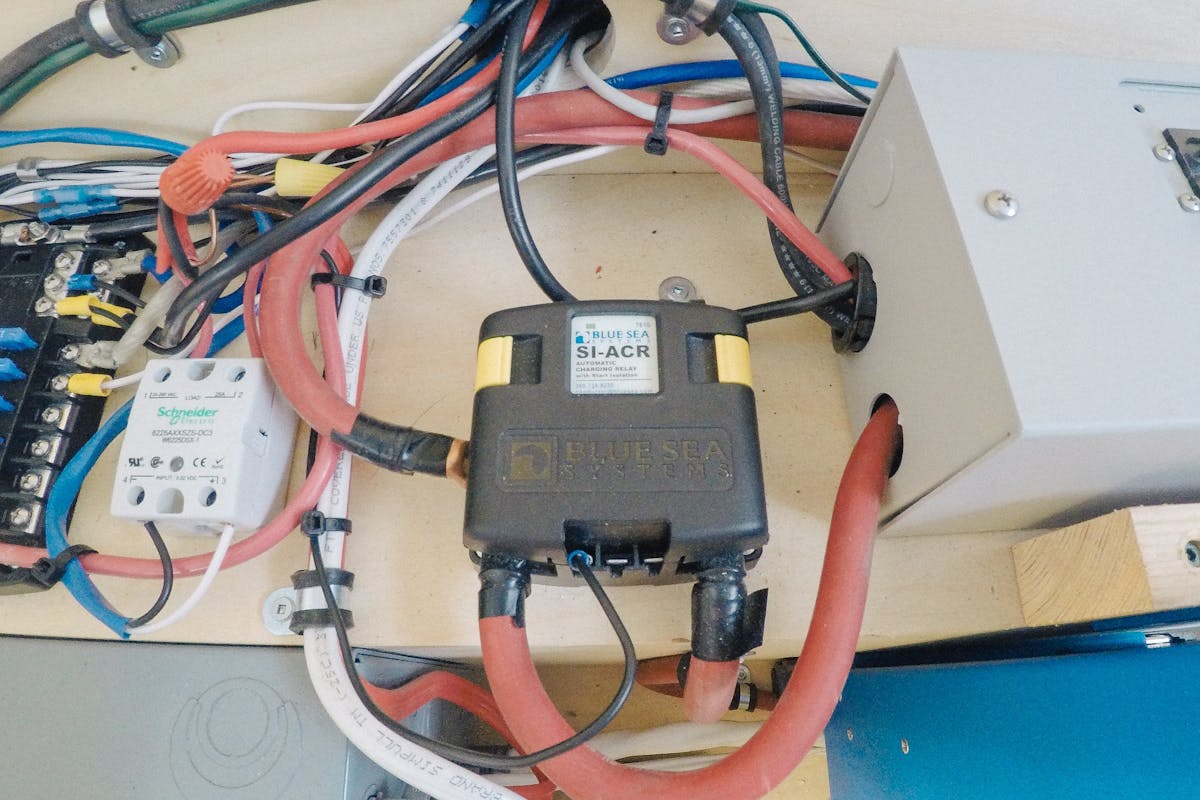

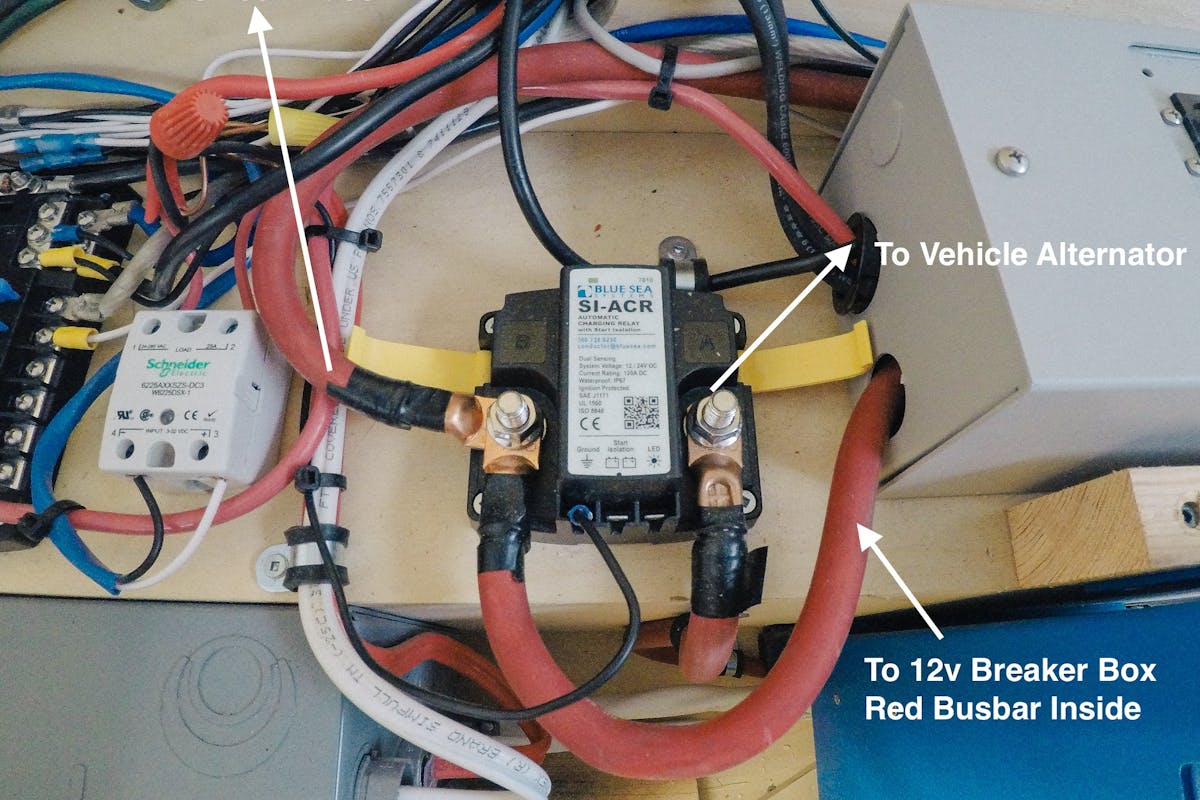

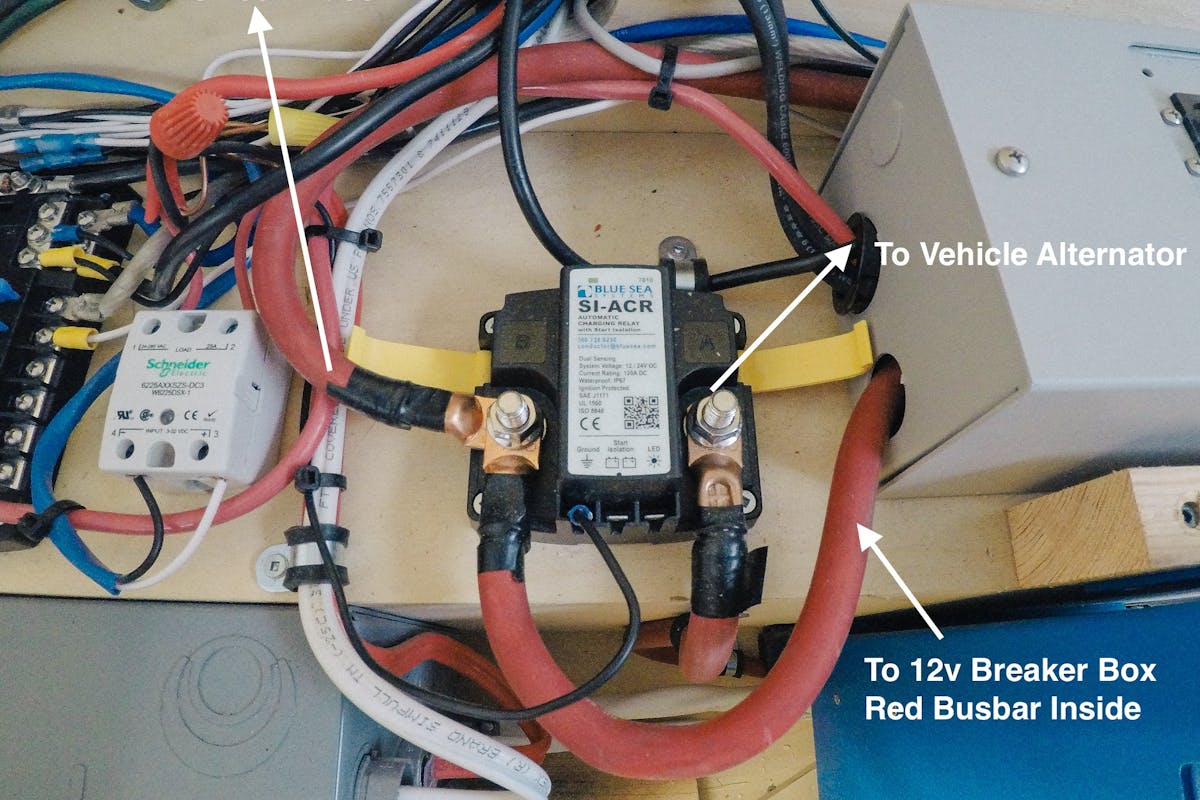

The Red Busbar inside of the breaker box has 3 positions I used up two of the positions described above and was able to use the third position for the ACR.

If you don’t remember from above, the ACR is an Automatic Charge Relay that allows me to charge the house batteries from the alternator once the vehicle starting battery is fully charged.

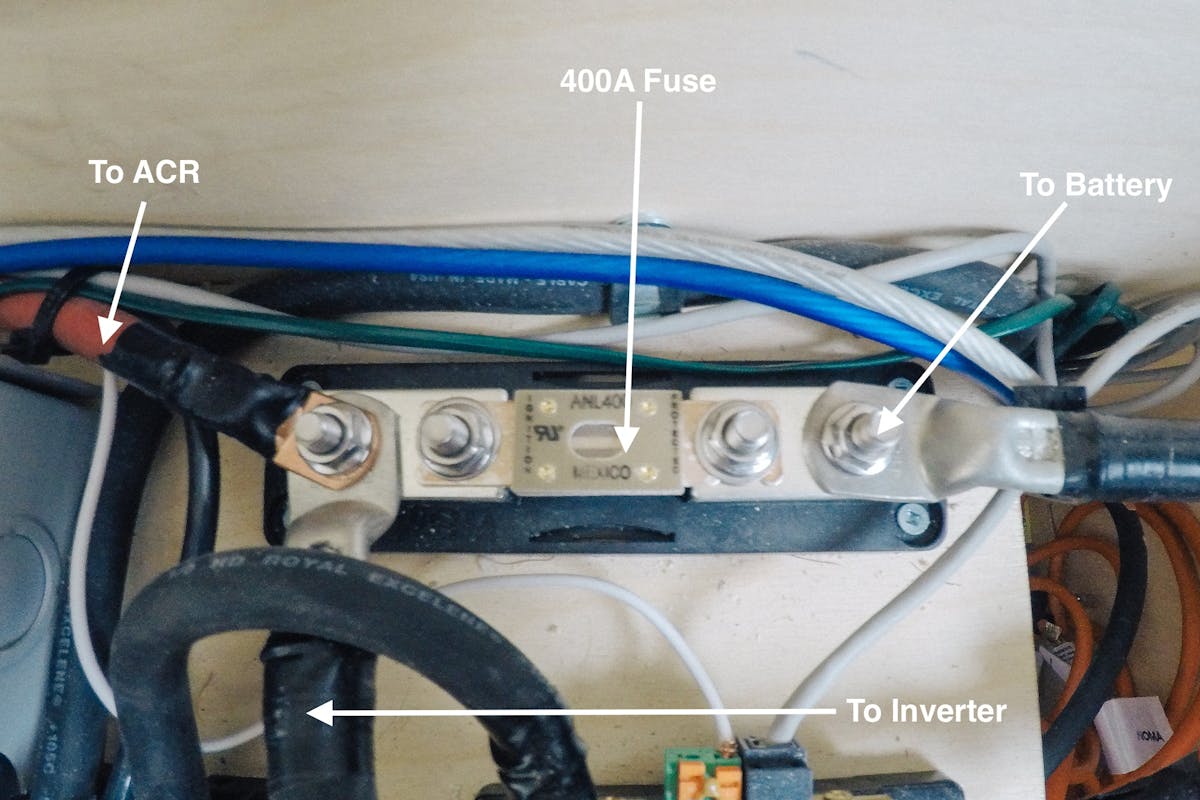

The ACR has three wires coming off it and they are all done using 1/0 welding cable. One wire runs from the Midnite Breaker box bus bar to the ACR, the second wire is the wire that connects the ACR to the vehicle battery / alternator and the third wire is connected to the 400A fuse between the (2) AGM batteries.

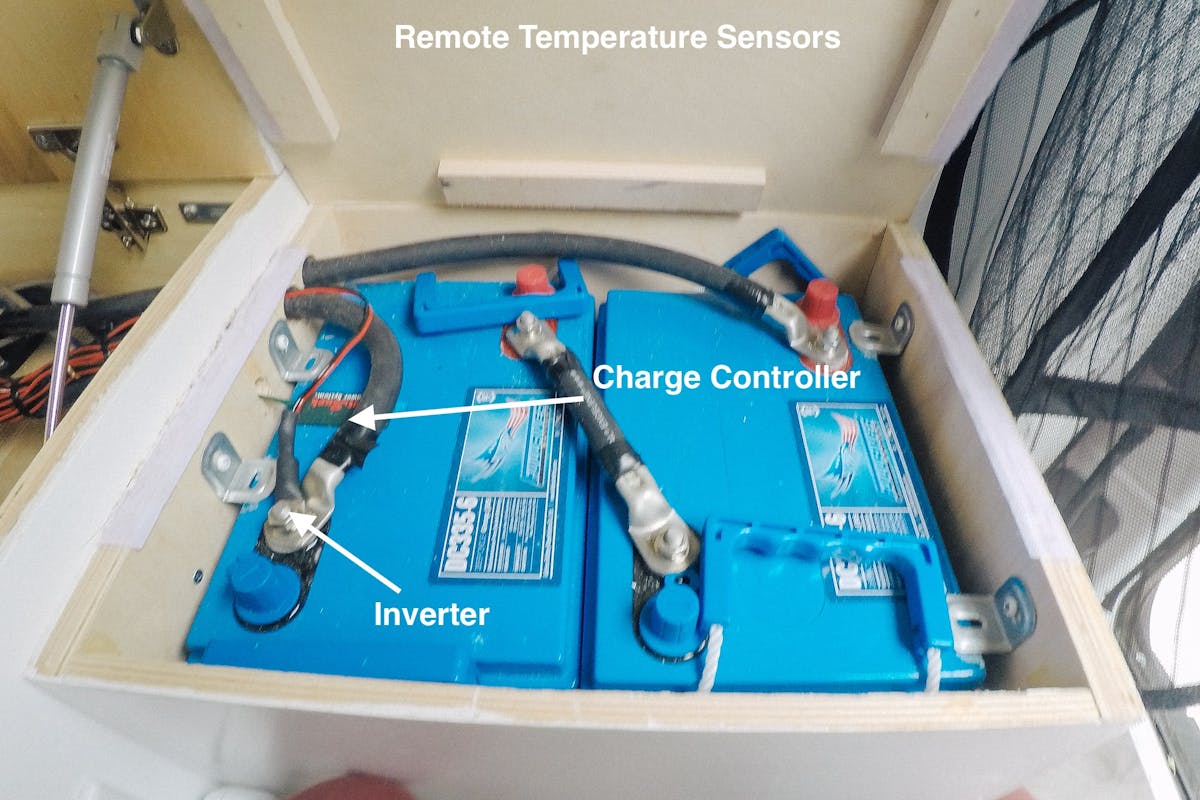

Ok lets move over to the batteries. I have (2) AGM batteries that are connected in series which gives my 12v 335aH Battery Bank. To connect the batteries together I used 4/0 welding cable. Then the remaining Red or positive side of the battery was connected to the 400A Fuse.

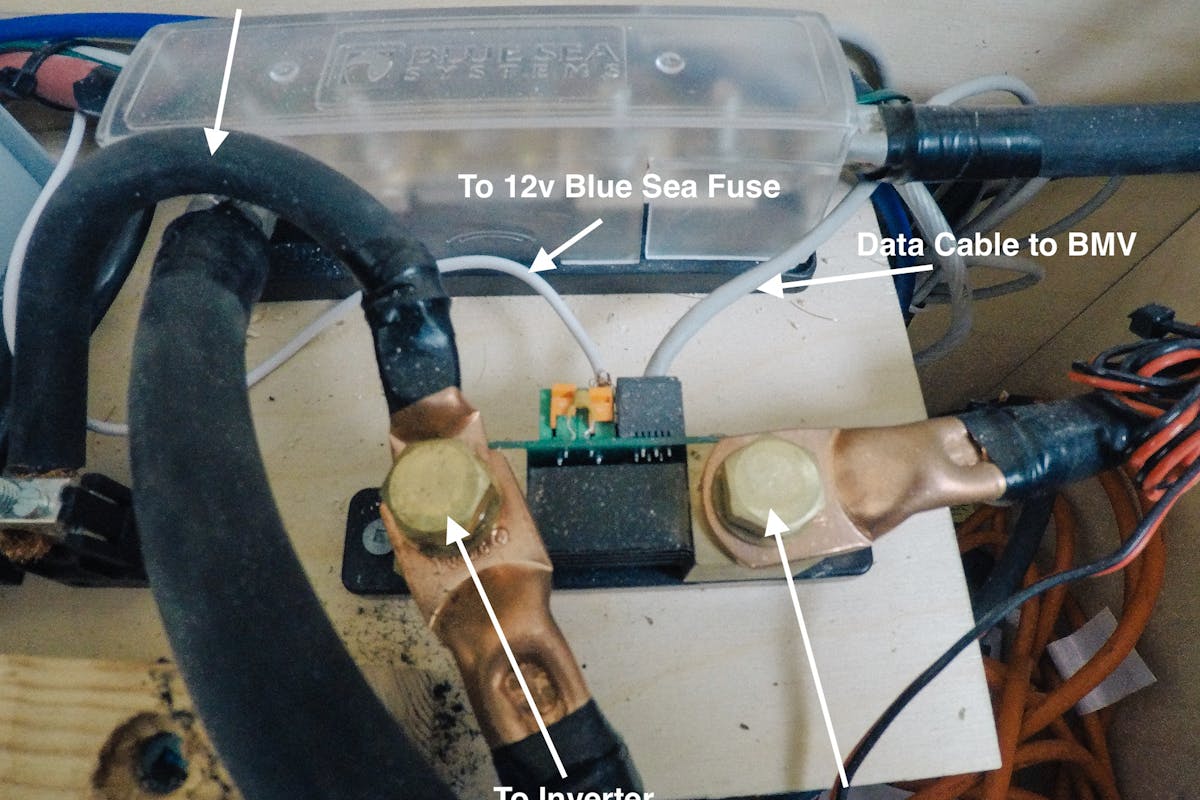

Leaving the Black or negative 4/0 cable from the batteries to be connected to the shunt.

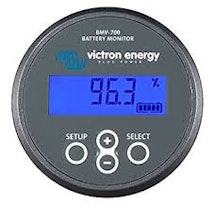

The shunt is needed in the system if you are wanting to run a battery monitor. For my van I used the Victron Energy BMV 702 which gives me readouts on battery capacity, time left on current charge, aH drawn from battery bank etc…. So it’s really nice to have.

I’m not 100% certain on how they work exactly but I do know the 500A shunt which is included in the BMV kit measures the electricity coming across the negative and uses some magic to display these numbers.

Basically the shunt is a breakpoint in the circuit and it has the ability to pull information as the electricity passes over it. On the shunt you will also need to install a small power wire which I just ran to the 12v BlueSea Fuse Panel and then the Data cable provided plugs into the shunt and the other end to the back of the BMV display.

When you purchase the BMV from Victron you can purchase a secondary bluetooth dongle and this allows you to get the system output numbers directly to an app on your smartphone.

Moving onto the batteries

In the battery photos you will see 2 other small gauge wires, both of these wires are remote temperature sensors. The green one you see stuck to the battery is for the charge controller and then the thin wire you see on the top left negative post is for the inverter. Both of these RTS are just wire directly into the respective device and it’s clearly labelled where they plug in.

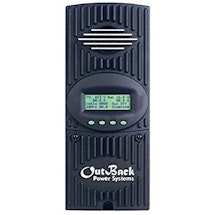

Next i’ll go over the wiring for the charge controller, basically we have 2 wires coming from the Midnite solar box these are 6awg welding cable one for the power to the charge controller and the other for the solar panels…. O yeah we also run a wire to ground the charge controller and that wire goes from the charge controller to the 12v Blue Sea Fuse Panel.

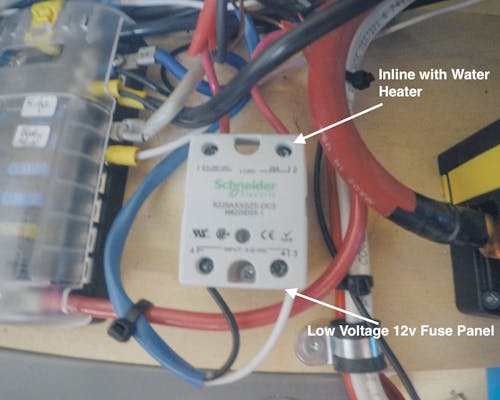

You will also notice the green wire for the RTS we talked about above and then I used some of the 14/2 in wall speaker wire to connect the bottom of the hot water relay to the AUX port of the charge controller. The charge controller is pretty straightforward to get everything wired up but will take some reading to ensure you program the controller properly to manage your batteries.

Mentioned above we talked about the large 400A fuse between the ACR and the batteries, I also ran a 4/0 welding cable wire from the same side as the ACR to bring power to the inverter.

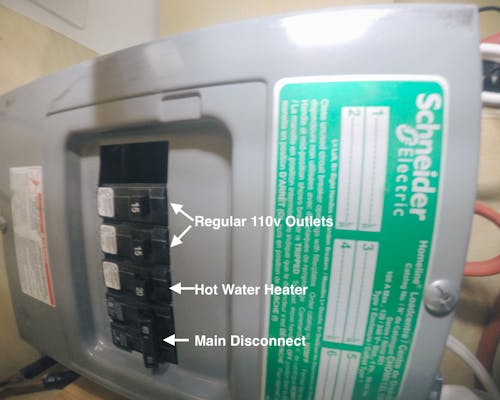

Then from the Inverter I used 6/3 ac wire to bring power into the Breaker Box I’m using for the 110V Circuits. The 6/3 wire is awful to work with especially when it’s -20c outside so try and get the wire warm before installing and it will make it easier to maneuver this beast of a wire.

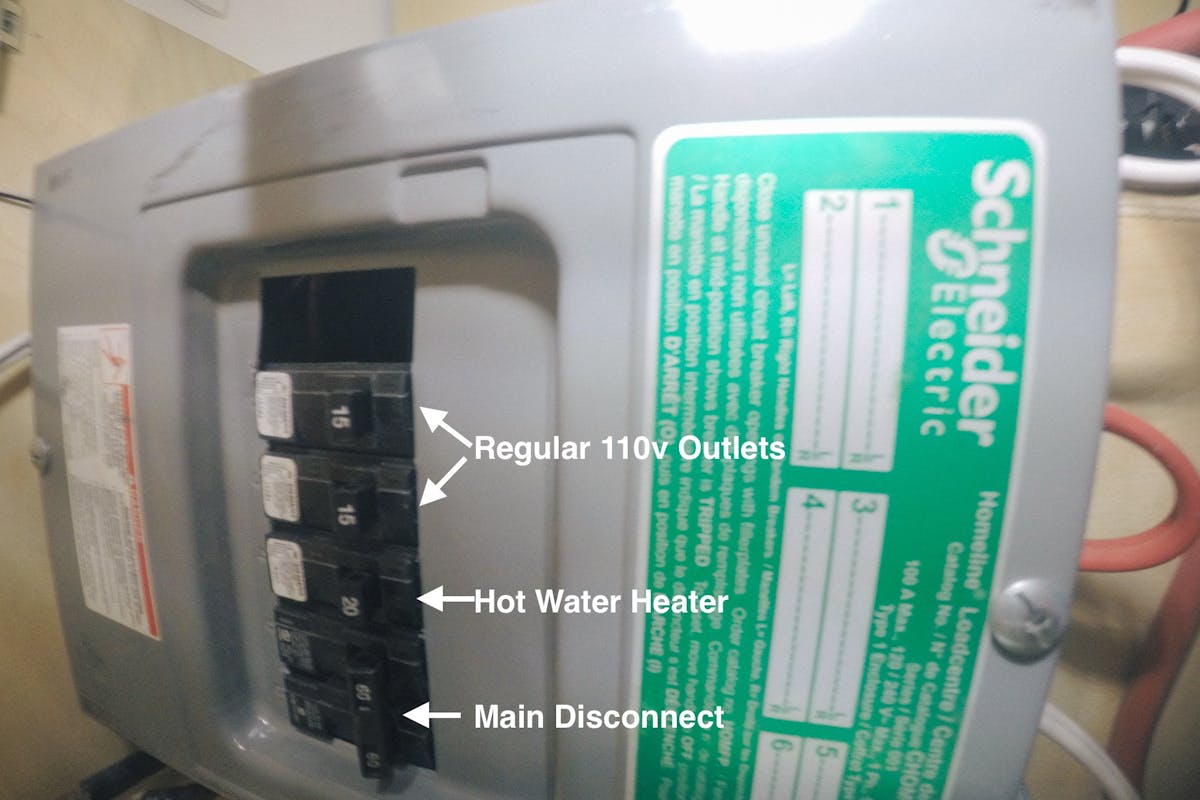

The breaker box has (2) 15A Circuits for the 110 Outlets (1) 20A Breaker for the Hot water Tank and then a Double 60A which is functioning as the main disconnect on the system since Im using a sub panel I had to hack the system this way to get a main disconnect.

The regular 110v wiring is fairly straight foward and I’m not going to go into much detail on that here. Just youtube how to wire an outlet and you will get a few thousand results. In fact i’ll take care of that for you just click here and watch one.

Hot Water Relay

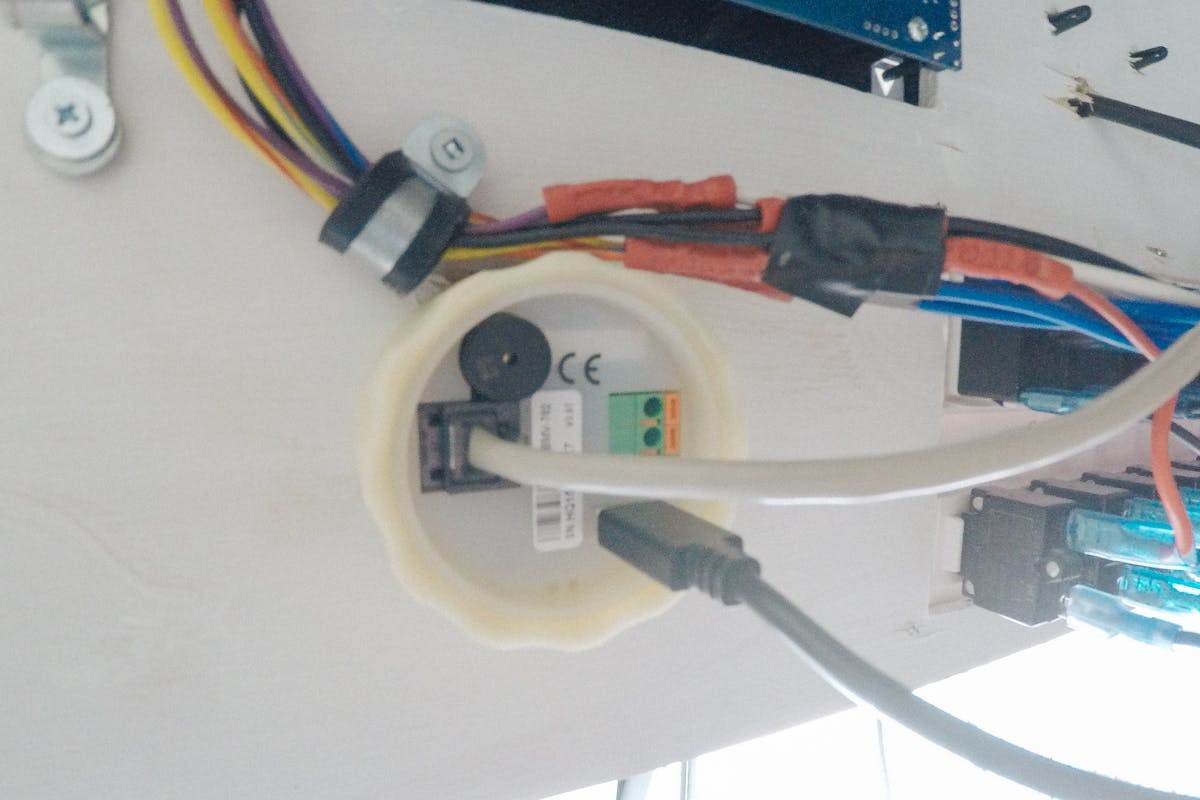

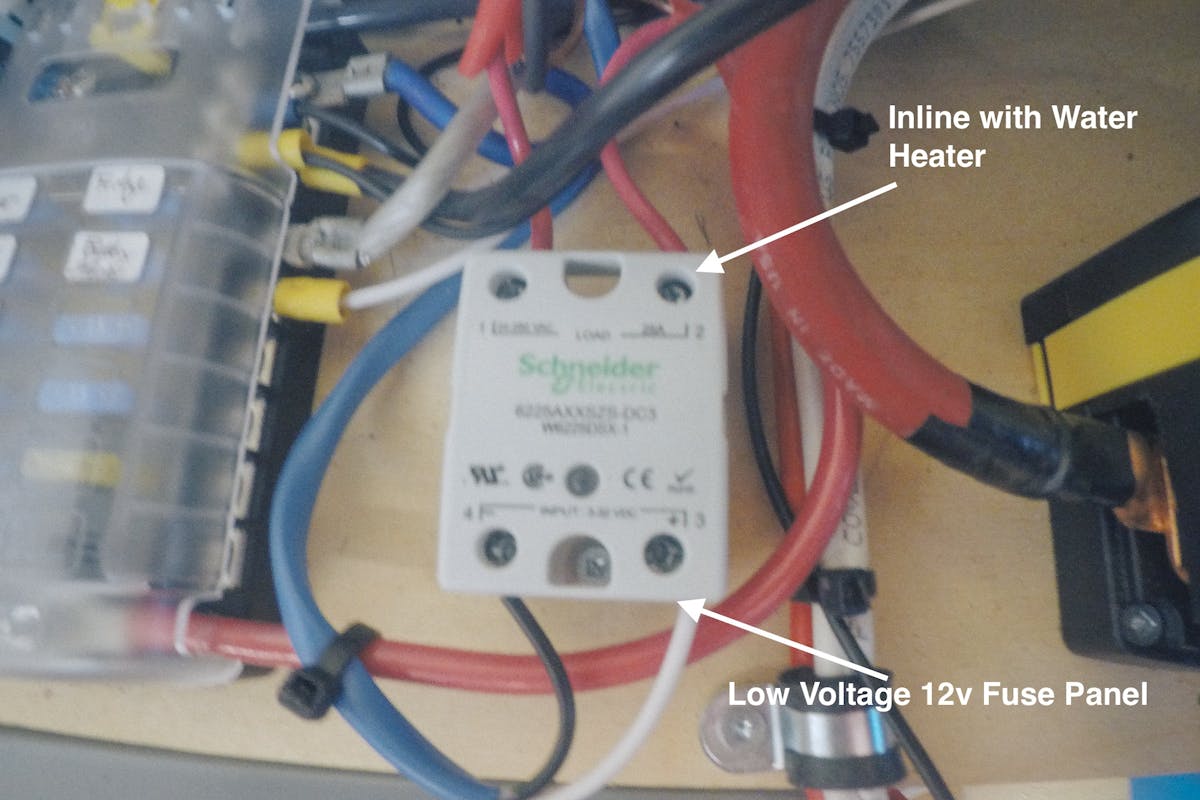

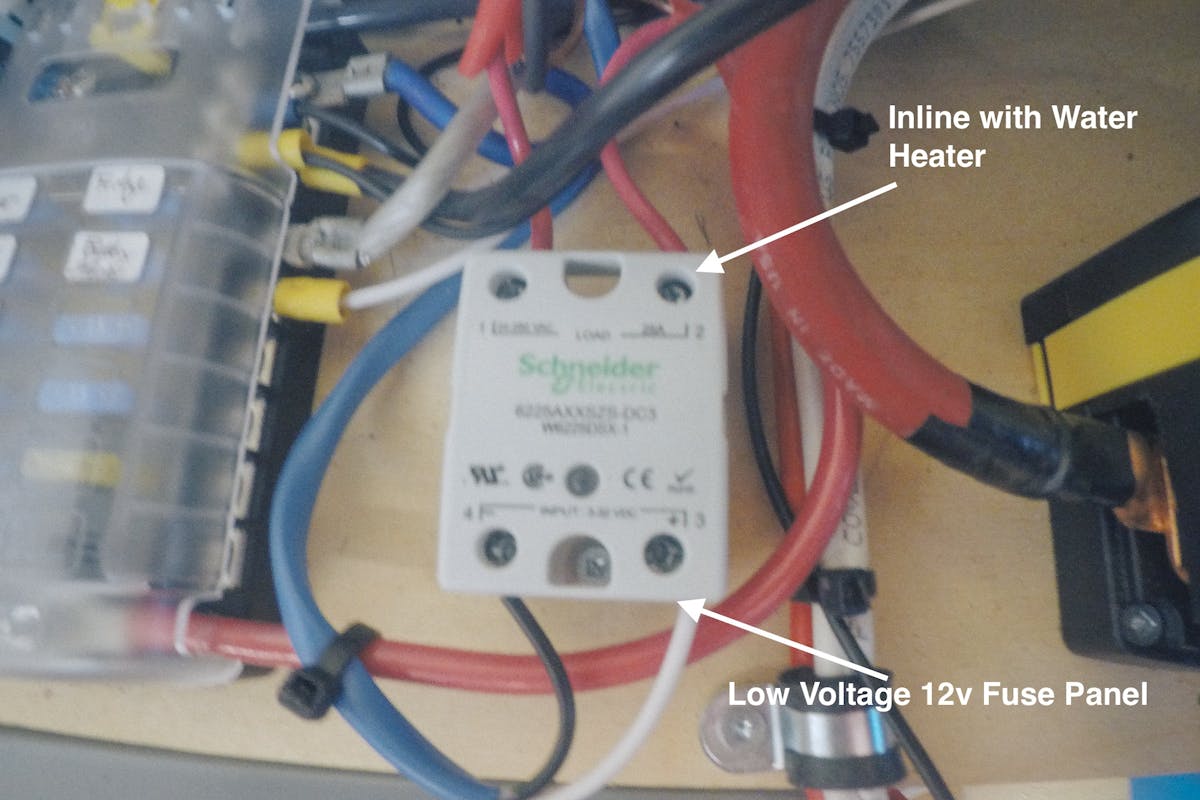

One thing I do want to touch on quickly is this little relay I used for my hot water tank

This little relay as you can see the bottom connects to the charge controller aux port and the top is placed inline with the positive wire going to the hot water heater. It’s a fairly simple install but what it does is allows you to almost trickle charge your water once the house batteries are full.

For those of you who are familiar with solar charging the charge controller will take your batteries through a few stages depending on the current voltage of the batteries.

In the morning your system will be in bulk mode and this means all available solar power will be sent to the batteries to charge them back up.

Once your batteries reach a nearly full charge which for my batteries total charge is 14.8 so my nearly full is around 14.2, the charge controller will then begin its absorb stage. The absorb stage of the charging cycle is a timed period for me 1.5 hours where the batteries will consume all the power they can at the highest voltage possible.

During this stage the relay will start to pulse a bit and send small amounts of energy into the hot water circuit. After the 1.5 hours of absorbing is complete then voltage will drop and you will enter a float stage. During float is when the relay will allow the most amount of electricity into the hot water tank as the charge controller at this point is only trying to maintain the battery level and not charge it anymore.

Hopefully that makes sense for the charging cycles and how the relay for my hot water tank works. Also keep in mind you can override the relay inside the charge controller and turn it to always on when driving and create your hot water that way as well. Also all of the voltage settings and absorb times will vary depending on the batteries you use in your system, final thing to note on this is what not every day will you hit the float or absorb stages which is fine it just means you won’t be making hot water that day unless going for a drive.

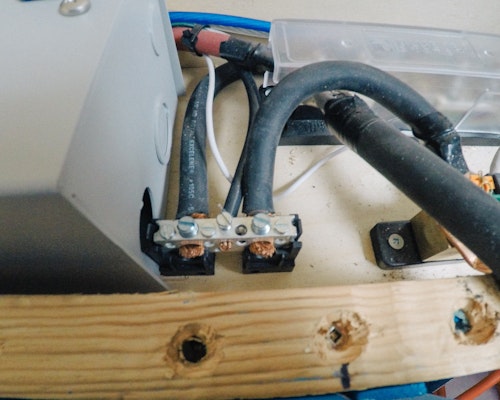

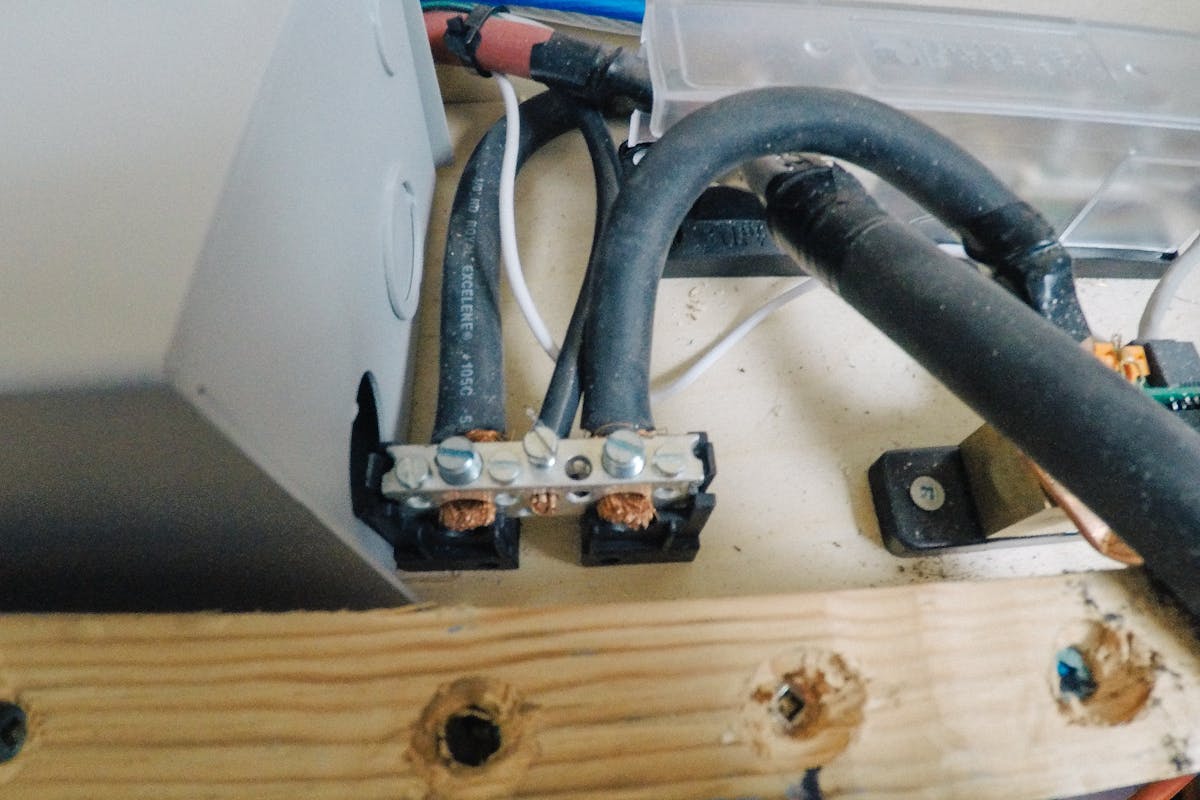

The last item on the system is the negative busbar which ties the house system ground the vehicle grounds all together.

On the left that wire goes to the vehicle to tie the grounds together

The middle wire is coming from the 12v Fuse Panel bringing all those together and the far right is heading to the shunt tying the negative side of the batteries to the rest of the system.

Cabinets Circuits

So the above outlines the main components of the solar and electrical system in the van. Once you have a decent understanding of how that all works getting all the 12v circuits hooked up is fairly easy.

From all of the circuits in the 12v system are going to get their power from the 12v Blue Sea Fuse Panel.

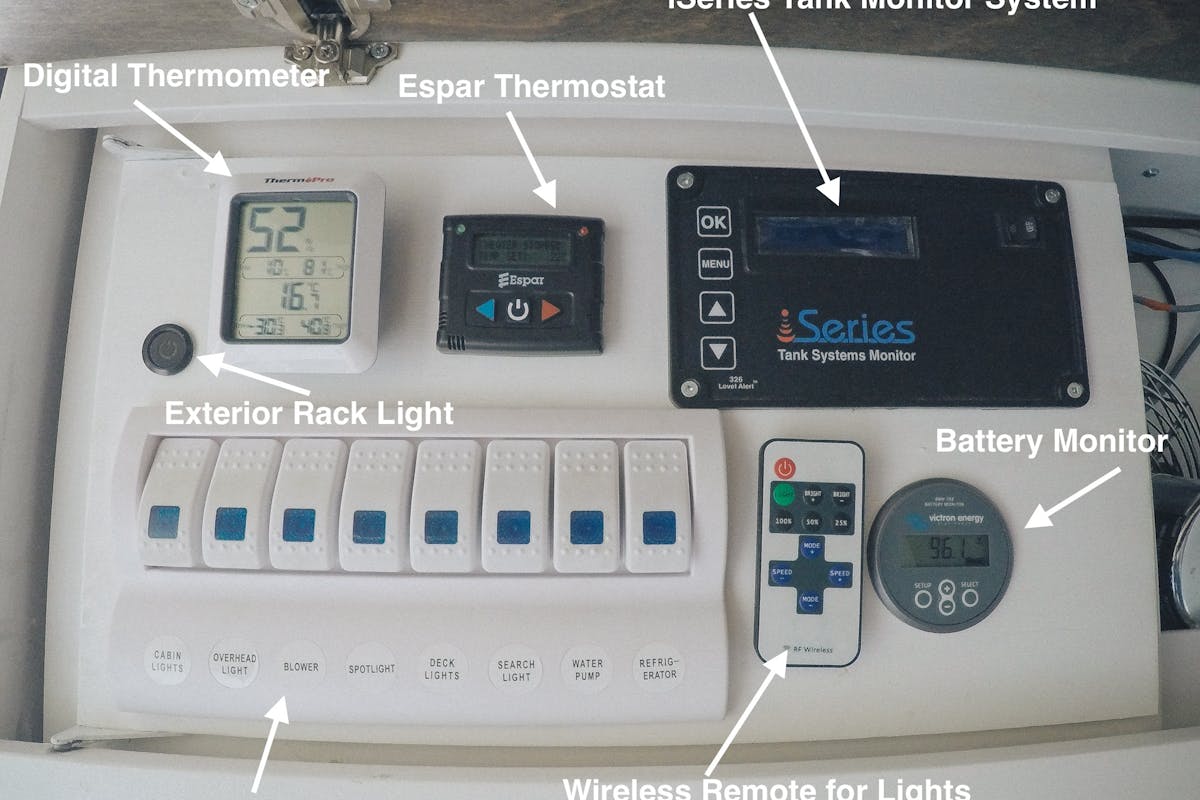

From this I ran the various wires up to the control panel as that is where I wanted the switches for the system to be located. When you look at my cabinet set up it probably looks intimidating but it’s really straightforward.

One thing to notice is that you don’t need to run a seperate wire from the Fuse Panel the cabinet for each and every device in the van. You can combine certain devices into the same circuits and still have them independently switched. In my van I believe I ran 3 wires so I could separate all my items into three circuits and then 3 additional wires for the tank meter system as each tank (grey, black and fresh) requires a pair.

Originally I had thought I ran more than enough wires into the cabinet but with the tank sensors it didn’t take long use them all up.

When wiring in all the components for the van if you’re going to use a central control station such as I did you are going to all the wires that you plan to have on the switch panel in the cabinet to be fed back to that cabinet.

Lower section where the bench will eventually be installed.

Above you can see all the wires coming in the bottom of the box from the passenger side bench and then the top wires are the wires coming in from the different devices.

Pro Tips

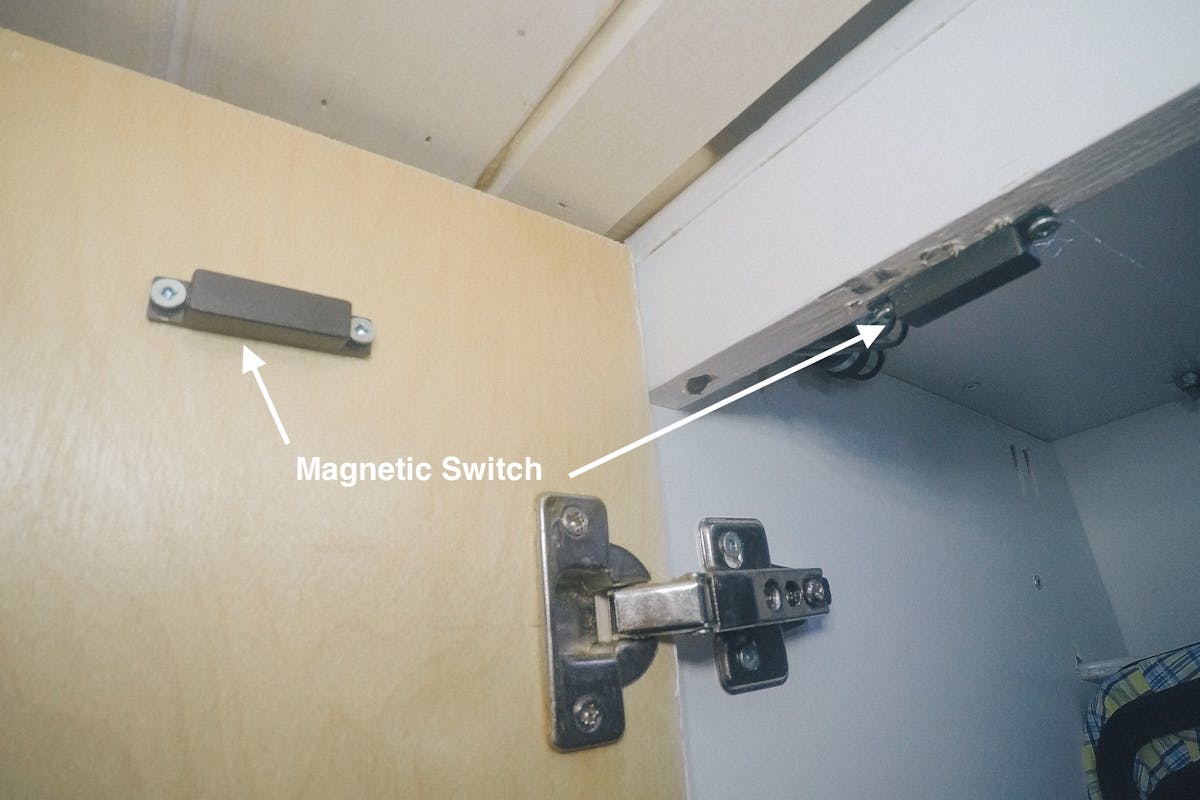

Magnetic Switches

On my van build I used some magnetic switches to trigger the wardrobe doors and side benches LED lights when opened. To most people it probably seems un necessary and…. You are right, but it was really cheap to buy the switches and I had lots of leftover LED light strips. So if you have the time I suggest doing it because it makes digging around in your closet in the middle of the night much much easier.

Marine Rocker Switch have a fuse

In my control panel area that I located all my switches you will see that I used 8 panel marine rocker switch. One thing to note is that each switch if you remove the white faceplate has its own built in fuse ranging from 5-15 A. So just keep this in mind as I originally had my fridge on a 5A switch and it popped the fuse on me before I knew about those fuses…. Lets just say i wasted a good couple hours troubleshooting a 10 second fix.

Make your own cables

I know online there are lots of websites that you can buy pre made cables for your solar system. After going through this I highly recommend buying lengths of cable and ends and building your own cables. The downside of making your own cables is that you need to purchase a tool for putting the lugs on the cable ends and crimping them properly, but I found that doing things this way made for a much cleaner install and I was never short of cable or trying to figure out how to use up additional unnecessary wire in the small cabinets.

Gallery

VIEW ALL